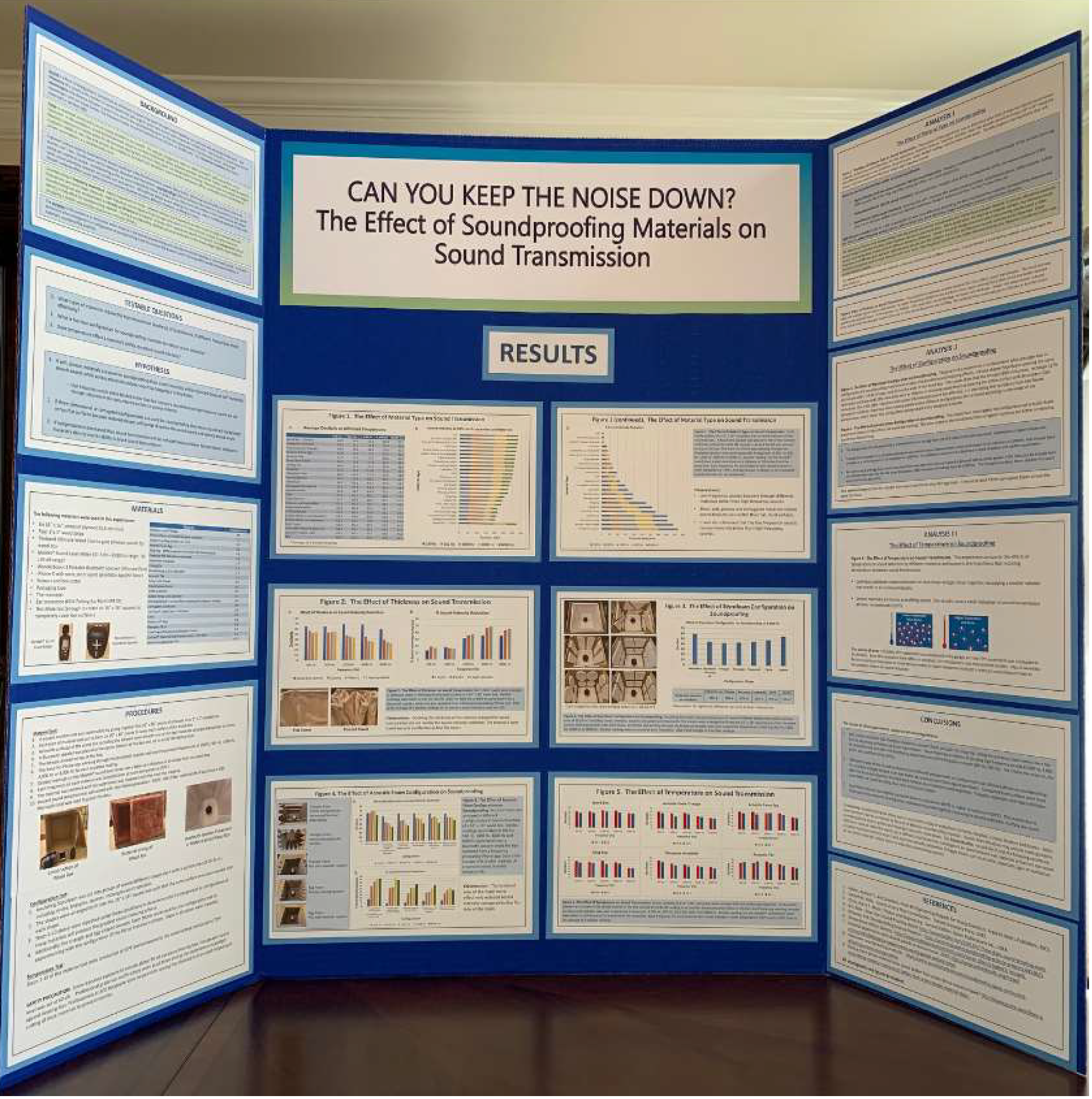

Can You Keep the Noise Down? The Effect of Soundproofing Materials on Sound Transmission.

Abstract:

Noise is unwanted sound and is an increasing problem in our society. For example, background noise can affect a student’s ability to perform in the classroom. In the workplace, sound levels have been shown to increase stress levels, blood pressure and heart rates which impact health as well as memory. Excessive noise in hospitals can impact a patient’s ability to rest, heal and recover and is linked to increased pain sensitivity. Even in doctor and lawyer offices, unwanted sound transmission of private conversations becomes a confidentiality issue. Soundproofing is the modification of a room or compartment so that sound waves are unable to escape. Soundproofing works by using materials to reduce or absorb sound. The purpose of this project is to determine which material is the best at soundproofing and reducing the decibel readings of transmitted sound. It will also determine what arrangement or configuration of soundproofing materials produce the greatest sound-reducing effects and if temperature affects a material’s soundproofing qualities.For the experimental method, an “anechoic chamber†(one that absorbs sound) was created by lining a 16†x 16†wood box with different materials (25 types) to determine which best reduced sound. A Bluetooth speaker was placed in the center bottom of the box and set to 80 dB reading in air and the lid was secured on top of the box. An iPhone Sonic Hz app working through the Bluetooth speaker was used to generate frequencies of 100 Hz, 500 Hz, 1000 Hz, 4000 Hz or 8000 Hz. Decibel readings on the Mestek® sound level meter were taken at a distance of 10 inches from the wood box. Experiments were repeated using different configurations of materials and at a lower temperature (55oF vs. 70oF).

The results of these experiments demonstrated that soft, porous materials (i.e. fiberglass insulation, acoustic foam, acoustic tile, shag rug, ceiling tile and terry cloth towels) were the best at absorbing and reducing sound transmission with a 40-58% sound reduction versus the wood box alone. These materials are better at blocking high frequency sounds (1,000 Hz, 4,000 Hz, 8,000 Hz) and less effective at reducing sound intensity of low frequency sounds (100 Hz, 500 Hz). High-frequency sound waves are lost through reflections in the many internal surfaces of porous materials. Absorption and diffusion work well with high frequency sounds since the vibration is less than low frequency sounds and more easily dispersed. Furthermore, different shapes of the insulating material and different arrangements or configurations had different effects on soundproofing. For example, triangle-shaped foam (43-46% sound reduction) was better at reducing sound than egg-shaped foam (29-35% sound reduction). Corrugated foam surfaces were more effective at sound reduction than flat foam surfaces due to better sound dispersion (i.e. 45% vs. 28% reduction with triangle foam at 4000 Hz). Triangle (28% sound reduction), rectangle (27% sound reduction) and trapezoid (23% sound reduction) shapes were better at sound proofing than circle (18% sound reduction) and square shapes (6% sound reduction). Additionally, sound transmission was reduced at lower temperatures (55oF) vs. higher temperatures (70oF). This may be due to molecules in the material slowing down and becoming closer together, increasing its density and better muffling the sound.

In summary, soundproofing has many uses in our society today in workplaces, factories, hospitals, schools, theaters and homes. Many noise problems can be prevented by the use of effective soundproofing materials. Results from this study may provide some guidance on making these spaces quieter and helping to keep the noise down.

Bibliography/Citations:

No additional citationsAdditional Project Information

Research Plan:

BACKGROUND RESEARCH/PURPOSE:

Noise is unwanted sound and is an increasing problem in our society. For example, background noise can affect a student’s ability to perform in the classroom. In the workplace, sound levels have been shown to increase stress levels, blood pressure and heart rates which impact health as well as memory. Repeated exposure to sounds above 85 dB can cause hearing loss and loud noise above 120 dB can destroy hearing. Excessive noise in hospitals can impact a patient’s ability to rest, heal and recover and is linked to increased pain sensitivity. Even in doctor and lawyer offices, unwanted sound transmission of private conversations is a confidentiality issue.

Engineers reduce noise by materials that absorb sound and make the environment quieter. Many factors affect how sound travels and how much noise reaches one’s ears. Sound waves can be reflected, absorbed and transmitted. Soundproofing is the modification of a room or compartment so that sound waves are unable to escape. Soundproofing works by using materials to reduce or absorb sound. Since hard, flat surfaces reflect sound and do not reduce noise, sound absorbing materials are usually soft and porous. Soft materials absorb sound, while porous materials reduce sound by trapping it in tiny holes. Smooth surfaces reflect sound while textured surfaces disperse sounds in different directions, muffling the sound.

Soundproofing is also frequency dependent. Higher frequencies are better reflected whereas low frequencies are able to pass through a barrier since low frequencies can travel longer distances. High-frequency sound waves are lost through reflections in the many internal surfaces in porous materials. Soundproofing can also be dependent on density or thickness of a material. A dense, thick material will absorb more sound. Since temperature affects density, it may affect the soundproofing material. Cooling a soundproofing material can cause molecules to slow down and get slightly closer together, occupying a smaller volume that results in an increased density.

The purpose of this project is to determine which material is the best at soundproofing and reducing the decibel readings of transmitted sound. It will also determine what arrangement or configuration of soundproofing materials produce the greatest sound-reducing effects and if temperature affects a material’s soundproofing qualities.

TESTABLE QUESTIONS:

- What types of materials reduce the transmission (or loudness) of soundwaves of different frequencies most effectively?

- What is the best configuration for soundproofing materials to reduce sound intensity?

- Does temperature affect a material’s ability to reduce sound intensity?

HYPOTHESES:

- If soft, porous materials are used for soundproofing then sound intensity will be reduced because soft materials absorb sound, while porous materials reduce sound by trapping it in tiny holes.

- High frequency sounds will be blocked better than low frequency sounds because high frequency sounds are lost through reflections in the many internal surfaces in porous materials.

- If three dimensional or corrugated configurations are used for soundproofing then more sound will be blocked versus flat surfaces because textured shapes will better disperse the sound waves and reduce sound levels.

- If temperature is decreased then sound transmission will be reduced because lower temperatures increase a material’s density and its ability to block sound transmission.

MATERIALS:

The following materials were used in this experiment.

- Six 16” x 16” pieces of plywood (0.5 cm thick)

- Four 1”x 1” wood strips

- Titebond Ultimate Wood Glue to glue plywood panels for wood box

- Mestek® Sound Level Meter (31.5 Hz – 8,000 Hz range; 30-135 dB range)

- Wonderboom2 Portable Bluetooth Speaker (Ultimate Ears)

- iPhone X with sonic pitch sound generator app (Hz Sonic)

- Scissors and box cutter

- Packaging tape

- Thermometer

- Ear protection (HDX Folding Ear Muff NPR 23)

- Test Materials (enough to create six 16” x 16” squares to completely cover box surfaces) include: acoustic foam triangle, Pink EcoTouch Unfaced Fiberglass Insulation, Airspace packing bubble 18 x 6 cm, acoustic egg foam, shag rug (100% polyester microfiber with latex backing), Foamular XPS extruded polystyrene, Styrofoam insulation, ceiling tile, bubble wrap 2.5 cm diameter, acoustic tile, terry cloth towel, polyethylene plastic, 100% polyester, bubble wrap 1 cm diameter, moving blanket, corrugated cardboard, Contact® cubed liner PVC vinyl, cork, felt Eco-fi® fiber, fiberglass cloth, craft foam (polyethylene standard foam), ConTact® textured grip premium liner PVC vinyl, heavy duty aluminum foil.

PROCEDURES:

Soundproofing Material Test:

- A square wooden box was constructed by gluing together five 16” x 16” pieces of plywood onto 1” x 1” wood strips.

- Each type of material was cut to form six 16” x 16” pieces to cover each surface of the wood box.

- All inside surfaces of the wood box including the lid were covered with one of the test materials using packaging tape to secure.

- A Bluetooth speaker was placed in the center bottom of the box and set to 80 dB reading in air.

- The lid was secured on top of the box.

- An iPhone app working through the Bluetooth speaker was used to generate frequencies of 100 Hz, 500 Hz, 1,000 Hz, 4,000 Hz or 8,000 Hz for each separate reading.

- Decibel readings on the Mestek® sound level meter were taken at a distance of 10 inches from the wood box.

- Each frequency for each material was tested 6 times at room temperature (70oF).

- The material was removed and the experiment was repeated with the next test material.

- Percent sound reduction was calculated with the following equation: 100% - (dB of test material/dB of wood box x 100). Microsoft Excel was used to graph the data.

SAFETY PRECAUTION: Since repeated exposure to sounds above 85 dB can cause hearing loss, the speaker sound level was set at 80 dB. Professional grade ear muffs where worn at all times during the experiments to protect against hearing loss. Professionals at ACE Hardware store helped with sawing the plywood and an adult helped with cutting of thick materials to prevent injuries.

Configuration test:

- Insulating Styrofoam was cut into groups of several different shapes each with a surface area of 28.26 in2, including circles, triangles, squares, rectangles and trapezoids.

- The shapes were arranged to fit into the 16” x 16” square box such that the same surface area was covered with each shape.

- Steps 4-10 above were repeated under these conditions to determine which arrangement or configuration of these materials will produce the greatest sound-reducing effects.

- Additionally, triangle and egg-shaped acoustic foam blocks were used for the configuration test by experimenting with the configuration of the flat or textured surfaces. Steps 4-10 above were repeated.

Temperature Test:

- Steps 3-10 of the material test were conducted at 55oF and compared to the material test conducted at 70oF.

REFERENCES:

- Adams, Richard C, and Goodwin, Peter H. Engineering Projects for Young Scientists. Franklin Watts Publishers, 2001.

- Goldsmith, Mike. Sound: A Very Short Introduction. Oxford University Press, 2015.

- Olson, Harry F. Music, Physics and Engineering. Second Edition. Dover Publications Inc., 2018.

- Kivi, Rose. How Does Sound Proofing Work? http://www.hunker.com/13412617/how-does-sound-proofing-work.

- Devaney, Erik. Soundproofing Science Projects. https://sciencing.com/soundproofing-science-projects-6452623.

- Temperature Affects Density. http://www.middleschoolchemistry.com/lesson plans/chapter3/ lesson6.

- Hospital experiments with sound panels to reduce noise. 2015. http://www.uofomhealth.org/news/ archive/201508/hospital-experiments-sound-panels-reduce-noise.

- Classroom soundproofing products. https://www.soundproofcow.com/soundproof-a-space-restaurant-office/classroom-soundproofing.

- Does a more dense material stop sound better than a less dense material does? http://www.quora.com/Does-a-more-dense-material-stop-sound-better-than-a-less-dense-material-does.