Force Analysis of Car Crash and Potential Improvements

Abstract:

Since the world entered the 21st century, technology, notably in the automobile industry, has experienced innovation and refinement at an incredible pace. However, as more advanced vehicle models are produced, people now direct their attention to the safety measure of automobiles. Making the protective structure, especially the bumper, safer yet lighter is now a dominant demand in the market. According to researchers, the most frequent type of collision that happens in the past is frontal collision, in which the bumper plays a crucial role at reducing the impact force to protect the driver and the passengers. This paper focuses on the analysis of a typical SUV frontal collision with a stationary obstacle. The simulation is based on the European New Car Assessment Programme (E-NCAP), standards in the automobile industry, and a simplified finite element model of a car.This paper investigates whether substituting the aluminum alloy bumper with carbon fiber composite bumper will improve its performance, specifically including bumper’s peak impact force (F), bumper intrusion (L), force absorption by the bumper (Q), upward displacement of the steering column hole (S1), backward displacement of the steering column hole (S2), the mass of the bumper (m), etc. After comparing and analyzing the substitution, it was discovered that although the performance improved, it is subtle. Notably, the mass of the bumper decreased by 43.19% after the substitution. However, the S1 value still exceeds E-NCAP standard, which is where future study should focus on.

Though the performance of the substituted bumper did not improve significantly, the mass is lowered by a considerable percentage. This study can be used to support future experiments about minimizing the mass of other parts of an automobile while subtly improving its performance at the same time.

Bibliography/Citations:

[1] L Kiran, Shrishail Kakkeri, Shridhar Deshpande. Proposal of hybrid composite materials for light commercial vehicle chassis. Materials Today, 2018,5(11): 24258-24267.

Additional Project Information

Project files

Research Plan:

Since the world entered the 21st century, the automobile industry has experienced innovation and refinement at an incredible pace. However, as more advanced vehicle models are produced, people now direct their attention to conceiving safer measures for automobiles. Making the protective structure, especially the front bumper, safer and lighter is now of increasingly dominant demand in the market. According to researchers, the most frequent type of collision that happens on the road is frontal collision, in which the bumper plays a crucial role at reducing the impact force that would endanger the driver and the passengers. However, the current aluminum alloy bumper that’s being used in various models has not shown high effectiveness. Thus, this paper focuses on the analysis of a typical SUV frontal collision with a stationary obstacle and the evaluation of the substitution of the aluminum alloy material with composite carbon fiber, a material that is remarkably lighter but may also provide higher safety index. The simulation is based on the European New Car Assessment Programme (E-NCAP) standards in the automobile industry and a simplified Finite Element model of a Toyota SUV.

Our goal of the experiment is to improve the performance of the front bumper of an automobile by substituting aluminum alloy with carbon fiber composite material, which is a lot lighter. There are two main trends in the automobile industry. One is light-weighted cars that are made because it is very energy efficient. The other trend is heavy-weighted cars, which are made with the belief that a strong structure is required to protect the driver and the passengers in the vehicle. Our experiment aims to reduce the mass of the bumper, improving its energy efficiency, while improving its performance in various safety measures at the same time. Aluminum alloy is the most frequently used metal for bumpers in the automobile industry because of aluminum’s light-weight property. However, we claim that carbon fiber composite material can be a good candidate for substitution. Our hypothesis is that changing the aluminum alloy material used for the front bumper of an automobile to composite carbon fiber material will improve its performance during an 100% frontal collision.

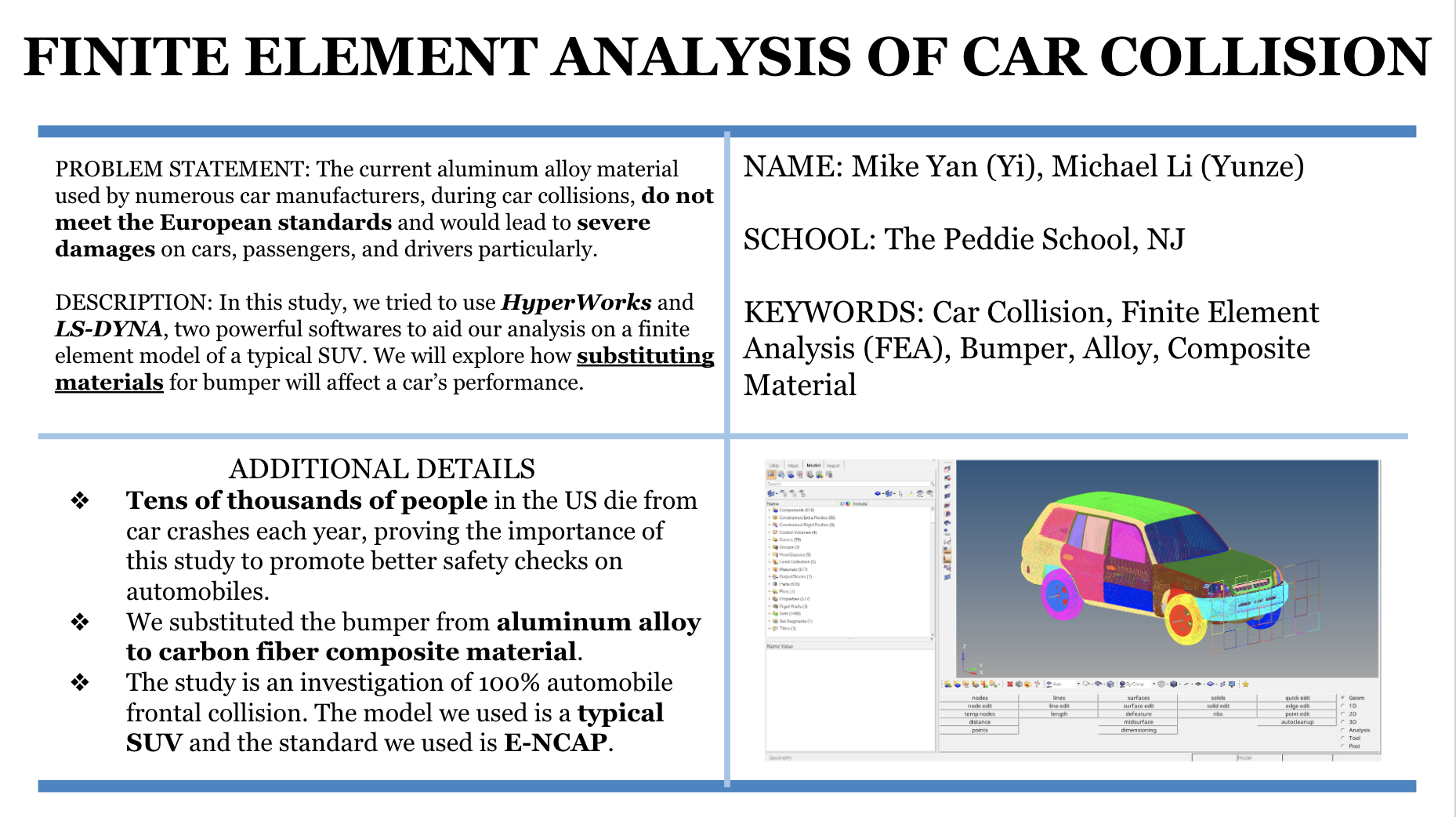

Our experiment will be done in a software called HyperWorks, a Finite Element Analyzing software developed by Altair Engineering. With the aid of LS-DYNA, a tool for calculation embedded in HyperWorks, and with several other sub-softwares within HyperWorks, such as HyperView and HyperMesh, we are able to simulate a car collision and generate and collect data pertinent to the simulations.

First, we, with the help of our sponsor, will create a Toyota SUV model using HyperWorks, which will then be exported as a K file. By importing the K file into LS-DYNA processor, we can obtain calculation results for various physical and mechanical properties of the model. Afterwards, we will import the model and calculations back into HyperView for running the simulation. Once the simulation is done, we will be able to carry out further analysis based on the data we will have acquired. As a result, we can evaluate the effectiveness of the optimization of the safety index of our model by substituting aluminum alloy with composite carbon fiber. When we have completed our analysis of the performance of the car with a carbon fiber bumper during a simulation, we will be able to draw our conclusion if carbon fiber is a more suitable material to use.

Throughout the entire experiment, our focus will be on running the simulations, gathering data, and analyzing the data. Finally, we will be able to formulate a paper discussing the effect of the substitution.

Below are reference articles we have looked at:

[1] L Kiran, Shrishail Kakkeri, Shridhar Deshpande. Proposal of hybrid composite materials for light commercial vehicle chassis. Materials Today, 2018,5(11): 24258-24267.

[2] Dong-Hyun Kim, Ku-Hyun Jung, et al. Improving pedestrian safety via the optimization of composite hood structures for automobiles based on the equivalent static load method. Composite Structures, 2017,176: 780-789.

[3] Kim D H , Choi D H , Kim H S . Design optimization of a carbon fiber reinforced composite automotive lower arm. Composites Part B Engineering, 2014, 58(8):400–407.

[4] Do-Hyoung Kim, Hyun-Gyung Kim, Hak-Sung Kim. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle. Composite Structures, 2015, 131:742-752.

[5] Deveci H A , Artem H S . Optimum design of fatigue-resistant composite laminates using hybrid algorithm. Composite Structures, 2017, 168:178-188.

[6] Liu P F , Xing L J , Zheng J Y . Failure analysis of carbon fiber/epoxy composite cylindrical laminates using explicit finite element method. Composites Part B: Engineering, 2014, 56:54-61.

Questions and Answers

1. What was the major objective of your project and what was your plan to achieve it?

a. Was that goal the result of any specific situation, experience, or problem you encountered?

b. Were you trying to solve a problem, answer a question, or test a hypothesis?

2. What were the major tasks you had to perform in order to complete your project?

a. For teams, describe what each member worked on.

3. What is new or novel about your project?

a. Is there some aspect of your project's objective, or how you achieved it that you haven't done before?

b. Is your project's objective, or the way you implemented it, different from anything you have seen?

c. If you believe your work to be unique in some way, what research have you done to confirm that it is?

4. What was the most challenging part of completing your project?

a. What problems did you encounter, and how did you overcome them?

b. What did you learn from overcoming these problems?

5. If you were going to do this project again, are there any things you would you do differently the next time?

6. Did working on this project give you any ideas for other projects?

7. How did COVID-19 affect the completion of your project?