Engineering novel functional bread through fortification with quercetin nanoparticles

Abstract:

Bibliography/Citations:

Bibliography

- Björck, I., Granfeldt, Y., Liljeberg, H., Tovar, J., Asp, N. G. (1994) Food properties affecting the digestion and absorption of carbohydrates. American Journal of Clinical Nutrition. 59, 699S-705S.

- Bhupathiraju, S. N., Tobias, D. K., Malik, V. S., Pan, A., Hruby, A., Manson, J. E., ... Hu, F. B. (2014). Glycemic index, glycemic load, and risk of type 2 diabetes: Results from 3 large US cohorts and an updated meta-analysis. The American Journal of Clinical Nutrition, 100(1), 218–232.

- Astrup, A., Dyerberg, J., Elwood, P., Hermansen, K., Hu, F. B., Jakobsen, M. U., Kok, F. J., Krauss, R. M., Lecerf, J. M., LeGrand, P., Nestel, P., Risérus, U., Sanders, T., Sinclair, A., Stender, S., Tholstrup, T., Willett, W. C. (2011). The role of reducing intakes of saturated fat in the prevention of cardiovascular disease: where does the evidence stand in 2010? American Journal of Clinical Nutrition. 93, 684-6888.

- Holubková, A., Penesová, A., Šturdík, E., Mošovská, S., Mošovská, L. (2012) Phytochemicals with potential effects in metabolic syndrome prevention and therapy. Acta Chimica Slovaca, 5, 186-199.

- Coe, S., & Ryan, L. (2016). White bread enriched with polyphenol extracts shows no effect on glycemic response or satiety, yet may increase postprandial insulin economy in healthy participants. Nutrition Research, 36(2), 193–200.

- Boots, A. W.; Haenen, G. R. M. M.; Bast, A. (2008) Health effects of quercetin: From antioxidant to nutraceutical. European Journal of Pharmacology, 585, 325−337.

- Azuma, K., Ippoushi, K., & Terao, J. (2010). Evaluation of tolerable levels of dietary quercetin for exerting its antioxidative effect in high cholesterol-fed rats. Food and Chemical Toxicology, 48, 1117–1122.

- Guo, Y., & Bruno, R. S. (2015) Endogenous and exogenous mediators of quercetin bioavailability. The Journal of Nutritional Biochemistry, 26, 201–210.

- Gao, Y., Wang, Y., Ma, Y., Yu, A., Cai, F., Shao, W., Zhai, G. X. (2009) Formulation optimization and in situ absorption in rat intestinal tract of quercetin-loaded microemulsion. Colloids and Surfaces B: Biointerfaces, 71, 306–314.

- Karadag, A.; Yang, X. Q., Ozcelik, B.; and Huang, Q. R. (2013) Optimization of Preparation Conditions for Quercetin Nanoemulsions Using Response Surface Methodology. Journal of Agricultural and Food Chemistry, 61, 2130-2139.

- Karadag, A.; Ozcelik, B.; and Huang, Q. R. (2014) Quercetin sub-micrometer suspensions produced by high-pressure homogenization, Journal of Agricultural and Food Chemistry, 62, 1852-1859.

- Lu, M. W.; Ho, C.-T.; Huang, Q. R. (2017) Improving quercetin dissolution and bioaccessibility with reduced crystallite sizes through media milling technique. Journal of Functional Foods. 37, 138-146.

- Lucas-Abellań, C.; Fortea, I.; Gabaldoń, J.A.; Nuń̃ez-Delicado, E. (2007) Encapsulation of quercetin and myricetin in cyclodextrins at acidic pH. Journal of Agriculture and Food Chemistry. 56, 255−259.

- Yadollahi, R.; Vasilev, K.; Simovic, S. (2015) Nanosuspension Technologies for Delivery of Poorly Soluble Drugs. Journal of Nanomaterials, 216375 (1-13).

- Lu, X. X.; Li, C.; and Huang, Q. R. (2019) Combining in vitro digestion model with cell culture model: Assessment of encapsulation and delivery of curcumin in milled starch particle stabilized Pickering emulsions. International Journal of Biological Macromolecules, 139, 917-924.

- Lu, X. X.; Zhang, H. W.; Li, Y. Q.; and Huang, Q. R. (2018) Fabrication of milled cellulose particles-stabilized Pickering emulsions. Food Hydrocolloids, 77, 427-435.

- Liu, Q. R.; Zhang, D.; Huang, Q. R. (2021) Engineering miscellaneous particles from media-milled defatted walnut flour as novel food-grade Pickering stabilizers. Food Research International, 24, 110554.

- Huang, Q. Y.; Huang, Q. R.; Wang, Y.; Lu, X. X. (2022) Development of wet media milled purple sweet potato particle-stabilized pickering emulsions: The synergistic role of bioactives, starch and cellulose. LWT- Food Science and Technology, 155, 112964.

- Lu, X. X.; and Huang, Q. R. (2020) Nano/Submicrometer milled red rice particle-stabilized Pickering emulsions and their antioxidative properties. Journal of Agricultural and Food Chemistry, 68, 292-300.

- AACC, 2000, Approved Methods by American Association of cereal Chemists.

- Miclaus, M. O.; Filip, X.; Filip, C.; Martin, F. A.; Grosu, I. G. (2016) Highly sensitive solid forms discrimination on the whole tablet of the active ingredients in quercetin dietary supplements by NMR crystallography approaches. Journal of Pharmaceutical and Biomedical Analysis. 124, 274-280.

- Zheng, T.; Yin, Z. Y.; Huang. Q. R. (2022) Assessment of digestion, absorption, and metabolism of nanoencapsulated phytochemicals using in vitro and in vivo models: A perspective paper. Journal of Agricultural and Food Chemistry, 70, 4548-4555.

- Ting, Y. W.; Jiang, Y. K.; Lan, Y. Q.; Xia, C. X.; Rogers, M. A.; and Huang, Q. R. (2015) Viscoelastic emulsion improved the bioaccessibility and oral bioavailability of crystalline compound: A mechanistic study using in vitro and in vivo models, Molecular Pharmaceutics, 12, 2229-2236.

Additional Project Information

Research Plan:

Research Objectives

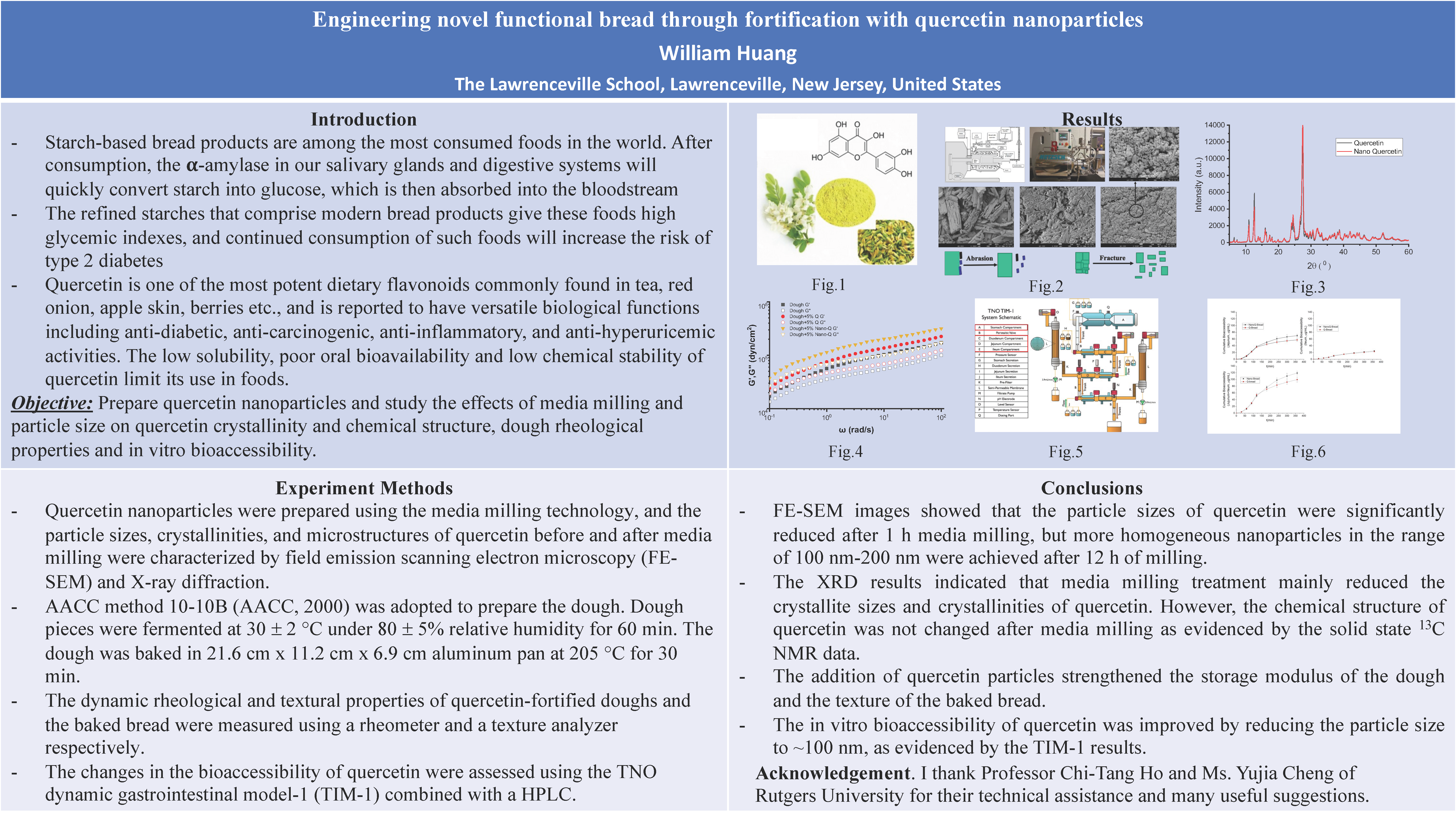

- Prepare quercetin nanoparticles using media milling technique, and study the effect of processing time on the quercetin particle size reduction

- Study the effect of quercetin size reduction on quercetin crystallinity and chemical structure

- Fortify the dough with quercetin particles, and study the effects of quercetin size on the rheological properties of dough

- Investigate the impact of quercetin particle size on the bioaccessibility of quercetin in bread using the TNO dynamic gastrointestinal model-1 (TIM-1)

Experimental Procedures

- Preparation of Quercetin Nanoparticles. Quercetin nanoparticles of different sizes are to be prepared using media milling technology. After that, the quercetin water mixtures will be frozen overnight and then dried in a freeze-dryer.

- Particle Size Measurement. Quercetin particle sizes will be measured by using a field emission scanning electron microscope (FE-SEM).

- X-ray Diffraction (XRD). The crystallinity of different quercetin particles (before and after milling) will be determined by using XRD, calculated using the following equation:

Degree of crystallinity (%) = Ic/(Ic + Ia) × 100%

Here, Ic = the integrated area of the crystalline phase and Ia = the integrated area of the amorphous phase [16]

- Solid State 13C NMR. The impact of media milling on the chemical structure of quercetin particles will be measured using a Solid State 13C NMR [21].

- Preparation of Bread. AACC method 10-10B [20] will be adopted to prepare the dough. Dough pieces will be fermented at 30 ± 2 °C under 80 ± 5% relative humidity for 60 min. The dough will be baked in 21.6 cm x 11.2 cm x 6.9 cm aluminum pan at 205 °C for 30 min.

- Rheological Properties of Dough. The dynamic rheological properties of quercetin-fortified doughs will be measured using a rheometer.

- In vitro Bioaccessibility. The changes in the bioaccessibility of quercetin in bread will be monitored using the TNO dynamic gastrointestinal model-1 (TIM-1) combined with a HPLC [22,23].

Questions and Answers

1. What was the major objective of your project and what was your plan to achieve it?

a. Was that goal the result of any specific situation, experience, or problem you encountered?

b. Were you trying to solve a problem, answer a question, or test a hypothesis?

Metabolic diseases like obesity, diabetes, hypertension, heart diseases etc. are extremely prevalent in today's world given the vast array of processed foods and their low nutritional value in addition to their high glycemic indexes. Current medical treatment methods are often expensive and sometimes even painful. My project aims to develop a preventative approach to reduce the risks of chronic diseases through fortification of natural antioxidants into dough products (e.g., bread). Flavonoids (i.e., quercetin) are a family of phytochemicals which have many health benefits. However, their multiple hydrophobic aromatic rings and high crystallinity mean that they have poor water solubility, limiting their broad food applications. Thus, my major objective is to develop a method to improve the water solubility of quercetin by reducing its particle size to nanoscale. Many previous methods to improve quercetin water solubility involved the use of synthetic or semi-synthetic chemicals which may be acceptable in pharmaceutical industry but are not acceptable in food industry due to the regulatory concerns. In this project, I used a simple yet highly efficient media milling technique to successfully prepare quercetin nanoparticles.

2. What were the major tasks you had to perform in order to complete your project?

The main tasks in my project were: milling the quercetin, baking the bread, analyzing properties of the milled quercetin, and evaluating the properties of the two fortified breads (one with pure quercetin and one with milled quercetin), and evaluate the bioaccessibility of quercetin in bread using the in vitro dynamic gastrointestinal (TIM-1) model.

3. What is new or novel about your project?

a. Is there some aspect of your project's objective, or how you achieved it that you haven't done before?

b. Is your project's objective, or the way you implemented it, different from anything you have seen?

c. If you believe your work to be unique in some way, what research have you done to confirm that it is?

My project is unique in that it is the first to study how nanosize quercetin particles differ from macroscale ones in terms of crystallinity and chemical structure. In addition, it is the first to investigate how the quercetin particle size may impact the rheological properties of dough and the bioaccessibility of quercetin in bread with an in vitro dynamic gastrointestinal (TIM-1) model. This model takes into account the digestion in the stomach and absorption in different parts of the small intestine. The TIM-1 model offers better predictability and reproducibility for the results, more accurately determining the effects of particle size on bioaccessibility in my project

4. What was the most challenging part of completing your project?

a. What problems did you encounter, and how did you overcome them?

b. What did you learn from overcoming these problems?

In completing my project, I encountered quite a few setbacks. Since bread has yet to be tested using the TIM-1 system, I had to develop my own procedure. Existing procedures for solid samples would not work because my sample would swell up when introduced to water, leading to difficulties during the TIM-1 feeding process. To solve this problem, the proper amount of bread samples and the fluids were optimized, as to control the viscosity of the final product and more easily feed the sample into the stomach of the TIM-1.

The main problem was time. Each run of the small intestine model took a whole day, with HPLC sample preparation and analyses taking several days. And since the TIM-1 machine was relatively old, I had lots of trouble with the system and keeping it in balance/maintaining consistency throughout trials. Each day seemed to present a new problem with the machine, whenever one thing was fixed, another always seemed to arise, constantly delaying the project more and more. Nevertheless, my very helpful lab mentor and grad student were always enthusiastic to help me through the process.

5. If you were going to do this project again, are there any things you would you do differently the next time?

I would definitely do more trials. As mentioned in the previous response, time was my greatest limiting factor, and if I had more time, I would first perfect my procedure and then do double, triple the trials that I did this time to really find out whether there is a significant improvement in bioaccessibility or not.

The main issue with my procedure is the pre-digestion aspect. In our process, we added alpha-amylase into the bolus before digestion to imitate the actual process of oral digestion in which alpha amylase in saliva breaks down the starches. However in our process, we underestimated the strength of alpha-amylase and did the artificial ‘chewing’ process for 5 minutes at 37.0 °C, which turned out to be too long, as in the collected samples, we found that the glucose release curves were staggered forward too much, meaning that the majority of the starch digestion has already been completed before reaching the small intestine. Also, the amount of saliva solution was too much. We had to reduce the amount of sample in each run, while increasing the amount of water/fluids in the feed to keep the total volume the same. We made the alpha amylase calculations in relation to the amount of water in the feed, which is unrealistic given the amount of bread we added to the solution. The combination of too much saliva solution and chewing for too long led to the overdigestion of the bolus before ingestion into the stomach. However, this pre-digestion does not affect the actual release curves for quercetin since alpha-amylase does not interfere or break down quercetin.

6. Did working on this project give you any ideas for other projects?

Yes, I have recently received a grant for a continuation of this project: one about the creation of healthy butters using compounds such as quercetin and forming oil-water emulsions that are able to hold quercetin particles in liquids, and therefore offer better bioaccessibility within the body, similar to the goals of my current fortification experiment. I also plan to develop novel functional butter by replacing triacylglycerol heavy cream (i.e., butterfat) with more healthy diacylglycerol oil. This functional butter will also be able to dissolve compounds like quercetin, further increasing its bioaccessibility. Butter/margarine is also very applicable to be put into many foods, increasing its potential as a vehicle for fortification.

7. How did COVID-19 affect the completion of your project?

One of the main issues that the pandemic brought was that the research facilities had not been used in a long time and as I said before, the TIM-1 gastrointestinal model was not in great shape. I ran into many problems throughout the process, including hardware but also software problems, and one day we even lost power for a brief moment, which interrupted the digestion sequence and meant that we had to restart the run again the next day.