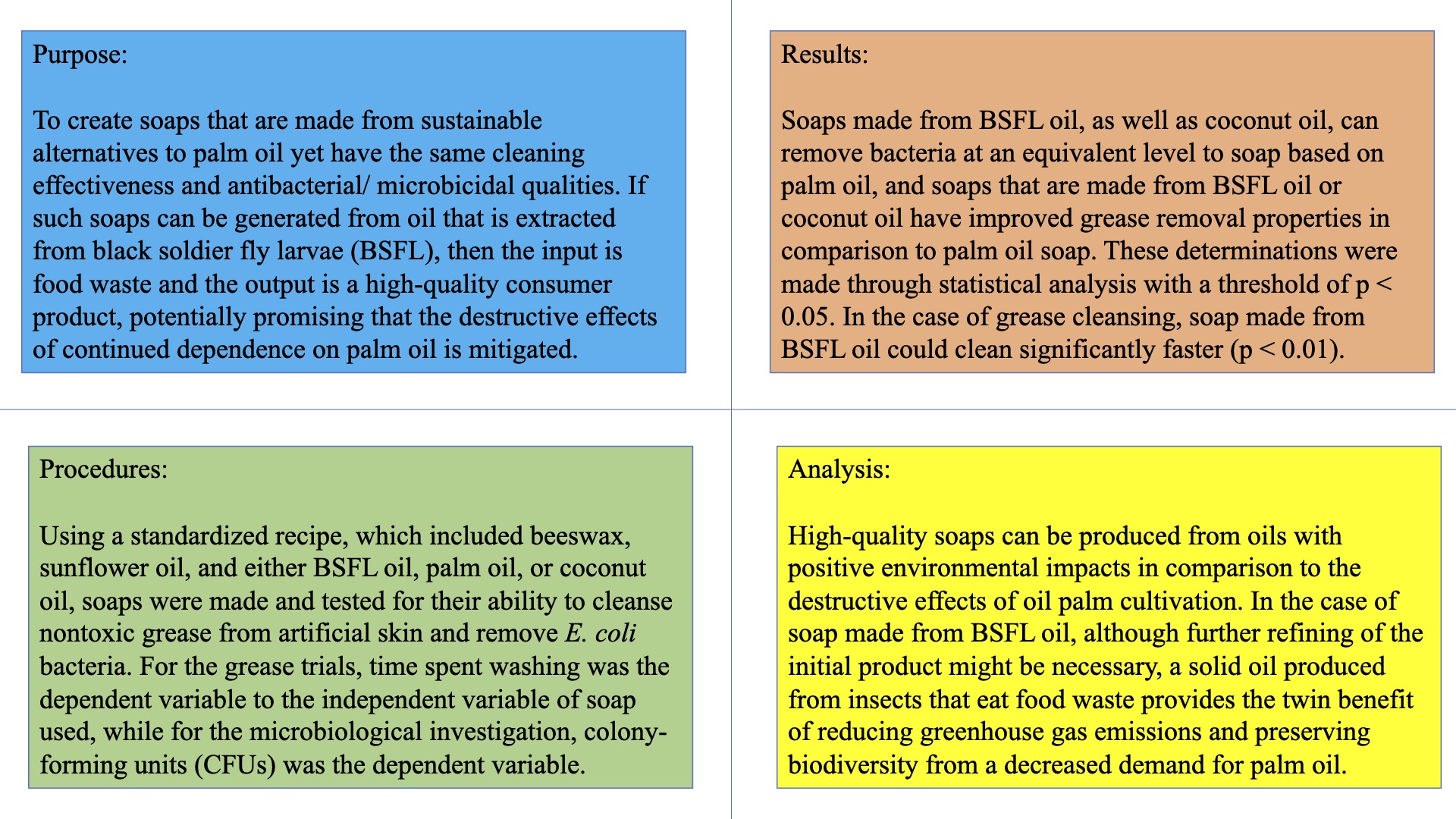

Scrubs with Bugs: Cleaning, Disinfecting, and Foaming Properties of Soaps Made with Sustainable Oils

Abstract:

Bibliography/Citations:

Ayanlowo, O., -Adeife, O. C., Ilomuanya, M., Ebie, C., Adegbulu, A., Ezeanyache, O., Odiase, O., Ikebudu, V., & Akanbi, B. (2022). African oils in dermatology. Dermatologic Therapy, 35(3), e14968. https://doi.org/10.1111/dth.14968

Burton, M., Cobb, E., Donachie, P., Judah, G., Curtis, V., & Schmidt, W. P. (2011). The effect of handwashing with water or soap on bacterial contamination of hands. International Journal of Environmental Research and Public Health, 8(1), 97–104. https://doi.org/10.3390/ijerph8010097

Di Genova, L., Cerquiglini, L., Penta, L., Biscarini, A., & Esposito, S. (2018). Pediatric age palm oil consumption. International Journal of Environmental Research and Public Health, 15(4), 651. https://doi.org/10.3390/ijerph15040651

Drewnowski, A., Rehm, C. D., Martin, A., Verger, E. O., Voinnesson, M., & Imbert, P. (2015). Energy and nutrient density of foods in relation to their carbon footprint. The American Journal of Clinical Nutrition, 101(1), 184–191. https://doi.org/10.3945/ajcn.114.092486

Edoh, A.K., & Ngo-Samnick, E.L. (2014). Cocoa Production and Processing. Pro-Agro Collection.

Ezenkwele, U. A., & Roodsari, G. S. (2013). Cultural competencies in emergency medicine: caring for Muslim-American patients from the Middle East. The Journal of Emergency Medicine, 45(2), 168–174. https://doi.org/10.1016/j.jemermed.2012.11.077

Cazzolla Gatti, R., Liang, J., Velichevskaya, A., & Zhou, M. (2019). Sustainable palm oil may not be so sustainable. The Science of the Total Environment, 652, 48–51. https://doi.org/10.1016/j.scitotenv.2018.10.222

Gesteiro, E., Guijarro, L., Sánchez-Muniz, F. J., Vidal-Carou, M., Troncoso, A., Venanci, L., Jimeno, V., Quilez, J., Anadón, A., & González-Gross, M. (2019). Palm oil on the edge. Nutrients, 11(9), 2008. https://doi.org/10.3390/nu11092008

Gibbs, F.W. (1939). The history of the manufacture of soap. Annals of Science, 4(2), 169-190. https://doi.org/10.1080/00033793900201191

Huang, Z. R., Lin, Y. K., & Fang, J. Y. (2009). Biological and pharmacological activities of squalene and related compounds: potential uses in cosmetic dermatology. Molecules, 14(1), 540–554. https://doi.org/10.3390/molecules14010540

Jagdish (2019). Hybrid coconut cultivation, yield, varieties for profit. Retrieved from https://www.agrifarming.in/hybrid-coconut-cultivation-yield-varieties-for-profit

Kim, Y. B., Kim, D. H., Jeong, S. B., Lee, J. W., Kim, T. H., Lee, H. G., & Lee, K. W. (2020). Black soldier fly larvae oil as an alternative fat source in broiler nutrition. Poultry Science, 99(6), 3133–3143. https://doi.org/10.1016/j.psj.2020.01.018

Jain, P., Wally, J., Townsend, T. G., Krause, M., & Tolaymat, T. (2021). Greenhouse gas reporting data improves understanding of regional climate impact on landfill methane production and collection. PloS One, 16(2), e0246334. https://doi.org/10.1371/journal.pone.0246334

Lovett, P.N. (2004). The Shea Butter Value Chain: Production, Transformation, & Marketing in West Africa. United States Agency for International Development.

Mertenat, A., Diener, S., & Zurbrügg, C. (2019). Black soldier fly biowaste treatment - assessment of global warming potential. Waste Management, 84, 173–181. https://doi.org/10.1016/j.wasman.2018.11.040

Murphy, D. J., Goggin, K., & Paterson, R. (2021). Oil palm in the 2020s and beyond: challenges and solutions. CABI Agriculture and Bioscience, 2(1), 39. https://doi.org/10.1186/s43170-021-00058-3

Ogunbiyi, A., & Enechukwu, N. A. (2021). African black soap: Physiochemical, phytochemical properties, and uses. Dermatologic Therapy, 34(3), e14870. https://doi.org/10.1111/dth.14870

Paterson, R. R. M., & Lima, N. (2017). Climate change affecting oil palm agronomy, and oil palm cultivation increasing climate change, require amelioration. Ecology and Evolution, 8(1), 452–461. https://doi.org/10.1002/ece3.3610

Ramli, U. S., Tahir, N. I., Rozali, N. L., Othman, A., Muhammad, N. H., Muhammad, S. A., Tarmizi, A., Hashim, N., Sambanthamurthi, R., Singh, R., Manaf, M., & Parveez, G.

(2020). Sustainable palm oil: the role of screening and advanced analytical techniques for geographical traceability and authenticity verification. Molecules, 25(12), 2927. https://doi.org/10.3390/molecules25122927

Rochmyaningsih, D. (2020, July 17). Claim that coconut oil is worse for biodiversity than palm oil sparks furious debate. Retrieved from https://www.science.org/ article/claim-coconut- oil-worse-biodiversity-palm-oil-sparks-furious-debate

Sanwlani, N., Evans, C. D., Müller, M., Cherukuru, N., & Martin, P. (2022). Rising dissolved organic carbon concentrations in coastal waters of northwestern Borneo related to tropical peatland conversion. Science Advances, 8(15), eabi5688. https://doi.org/10.1126/sciadv.abi5688

Son, Y. J., Choi, S. Y., Hwang, I. K., Nho, C. W., & Kim, S. H. (2020). Could defatted mealworm (Tenebrio molitor) and mealworm oil be used as food ingredients?. Foods, 9(1), 40. https://doi.org/10.3390/foods9010040

Tzompa-Sosa, D. A., Dewettinck, K., Provijn, P., Brouwers, J. F., de Meulenaer, B., & Oonincx, D. (2021a). Lipidome of cricket species used as food. Food Chemistry, 349, 129077. https://doi.org/10.1016/j.foodchem.2021.129077

Tzompa-Sosa, D. A., Dewettinck, K., Gellynck, X., & Schouteten, J. J. (2021b). Replacing vegetable oil by insect oil in food products: effect of deodorization on the sensory evaluation. Food Research International (Ottawa, Ont.), 141, 110140. https://doi.org/10.1016/j.foodres.2021.110140

Vermeil, T., Peters, A., Kilpatrick, C., Pires, D., Allegranzi, B., & Pittet, D. (2019). Hand hygiene in hospitals: anatomy of a revolution. The Journal of Hospital Infection, 101(4), 383–392. https://doi.org/10.1016/j.jhin.2018.09.003

Zou, Y., Hu, T., Shi, Y., Liao, S., Liu, J., Mu, L., & Chen, C. O. (2017). Silkworm pupae oil exerts hypercholesterolemic and antioxidant effects in high-cholesterol diet-fed rats. Journal of the Science of Food and Agriculture, 97(7), 2050–2056. https://doi.org/10.1002/jsfa.8009

Additional Project Information

Project files

Research Plan:

There is only one standard procedure by which the soap will be produced, known as a “hot process” because heat is added and the final product cures relatively quickly. In all cases, these mixtures are combined under a safety hood that provides adequate ventilation, and procedures are conducted under adult supervision while wearing protective Nitrile gloves, aprons, face shields, and goggles. Once protective equipment is checked to ensure tight seals, the following ingredients are combined: 135 grams sodium hydroxide (NaOH), 255 grams distilled water, 283 grams of sunflower (liquid) oil, 20 grams of beeswax, 30 grams of violet essential oil, and 566 grams of solid (saturated) oil—the composition of which is either palm, coconut, or BSFL. Aside from BSFL oil, all ingredients are common in high school laboratories at the concentrations that will be mixed, therefore none are deemed hazardous. To start, sodium hydroxide will be added to the water in small quantities (less than 20 grams at a time) and stirred thoroughly to ensure that all of the crystals dissolve and the heat is allowed to dissipate. Because the molar heat of solution is very high for sodium hydroxide, great care will be taken to ensure that the water does not boil. This means that the NaOH is added in these increments over a period of ten minutes and allowed to cool before further processing.

In a 4-quart (3.79 L) crock pot, the solid and liquid oils plus beeswax are combined and heated until the solid components melt. This mixture is stirred thoroughly with a hand blender until it appears homogeneous. At this point, seven grams of purple coloring agent (mica powder) are added for aesthetic effect and the sodium hydroxide solution is stirred into the oils over approximately one minute. When the mixture begins to thicken, which is described as reaching “trace” for soapmaking, violet essential oil is added for fragrance, mixed again, and the resulting viscous liquid is poured into silicone soap molds. After the soap is allowed to harden over a period of two days, 11 bars weighing 106 grams each are removed from their molds and allowed to cure for an additional 5 days on a shelf. In all, one batch of soap is made for each solid oil, as well as one additional recipe with coconut oil as the solid base that incorporates 20 grams of baking soda instead of beeswax for purported anti-grease and antibacterial properties. This fourth type of soap will be colored blue for differentiation.

To assess the abilities of soaps to clean grease from skin, a 5.0 x 0.5 centimeter line of black eye grease commonly used for sports will be placed on a 19.0 x 14.0 centimeter piece of silicone “practice” skin that is used for tattoo training. The skin will then be washed with consistent and standardized hand movements with lather derived from the soaps previously described and water that is at 24.1oC (the temperature of cold water from the sink). These repeated hand movements will clean the silicone skin until grease is removed to the point that it appears consistent, and the time taken to reach that state of cleanliness will be recorded. After use, practice skins will be washed thoroughly with dish soap and dried for repeated use. In total, 30 replicates for each type of soap will be performed and the average times compared using an analysis of variance (ANOVA) significance was determined with a Tukey honestly significant difference test (HSD).

Using another set of fresh “practice” skin, 0.1 mL of a culture made with school-safe Eschericia coli bacteria (Carolina Biological variety K-12) with a cell concentration of 9.7 x 106 colony forming units (CFUs) per mL will be placed on a 1.0 cm x 1.0 cm rectangle in the middle of each test surface. This concentration will be determined through serial dilution from 10-1 through 10-16 of the original culture and plating 0.2 mL on plates that contain tryptic soy agar (TSA). These silicone skin patches with inoculated bacteria will then be washed with cold water and lather from one of the selected soaps for a total of 30 seconds, except for one that will be left without any washing (positive control), one that is washed only in water (positive control), and one that is washed in a 10% bleach solution that is the laboratory standard for surface sterilization (negative control). After 30 seconds of washing—except for the “no wash” control—each rectangle will be rubbed with a sterile swab. Any recovered bacteria will then be transferred to a Petri dish containing sterile tryptic soy agar (TSA) and incubated overnight at 37oC to allow surviving E. coli to grow and be counted as colonies. Silicone skins will then be soaked in a 10% bleach solution for one hour, rinsed thoroughly and dried, then used for future experiments. After 24 hours, each Petri dish will be examined and colonies counted whenever visible. In total, 30 trials will be performed for each type of soap, as well as 30 trials for the two positive controls and the negative control. Given that these trials consisted of 7 different treatments (no washing, water only, palm oil soap, coconut oil soap, BSFL oil soap, baking soda soap, and 10% bleach solution), results will be analyzed using an ANOVA and significance determined with a Tukey honestly significant difference test (HSD).

In order to assess the quality of foam produced by these different soaps, a 1.0 gram sample of each will be placed in 50.0 mL of water and a double whisk milk frother (brand Pachaco) will be allowed to generate lather for a period of 60 seconds (1 minute). The resultant foam will be recovered with a plastic spoon and transferred to a ruled microscope slide with small squares in the focal area that measure 2.0 mm on each side. A cover slip will be placed on top of this foam, and pressure applied until one layer of bubbles can be resolved. Measurements will then be made for bubble size and quantity.

Questions and Answers

1. What was the major objective of your project and what was your plan to achieve it?

My plan was to investigate the effectiveness of soaps that are made from more sustainable ingredients in order to lessen our impact on the environment. To do this, I needed to measure the cleaning and disinfecting qualities of soaps made from these sustainably-sourced ingredients, which include oils made from black soldier fly larvae, coconuts, sunflower seeds, and beeswax from the European honeybee (also New Jersey's official state insect).

a. Was that goal the result of any specific situation, experience, or problem you encountered?

I have always been concerned about the environment and the destruction of natural habitats for economic gain, like what happens when oil palm plantations are established in Latin America, Africa, and Asia through the destruction of tropical forest. When I worked on a school team last year to reduce food waste using the black soldier fly, and I discovered that oil could me made out of it, so I thought that this would be a good opportunity to test how this oil would compare to palm oil and other oils that can be produced more sustainably. Soap appeared to be an important consumer product to test, because most people in the developed world use it daily. It is the developed world that consumes most of the world's resources, and therefore it is essential to ensure greater environmental sustainability with products that these societies consume.

b. Were you trying to solve a problem, answer a question, or test a hypothesis?

I was trying to solve an environmental problem by exploring if oil that comes from black soldier fly larvae, insects that are known to be voracious consumers of food waste (a potent source of greenhouse gases), could be used to make consumer products. If I could make soap from black soldier fly oil, and it worked as well or better than soaps made from palm oil, I could recommend a way to both combat biodiversity loss through deforestation on oil palm plantations and fight global warming by preventing food waste from being buried in landfills.

2. What were the major tasks you had to perform in order to complete your project?

a. For teams, describe what each member worked on.

I completed all tasks on my own, under the supervision of my adult mentor. I made the soaps, performed the washing experiments, performed the bacterial inoculation experiments, and analyzed the foam under the microscope. On a few occasions, friends helped me with data collection, but not to the extent where I was not performing the tasks. They merely wrote down what I was observing, and I analyzed all of the data.

3. What is new or novel about your project?

My project takes sustainability in a new direction, because I am using a substance derived from insect agriculture and transforming it into a cosmetic product. As such, I am turning trash (food waste) into treasure (high-quality soap). This is novel because while feeding insects on food waste and using them for human or animal consumption has been tried previously, no one in my knowledge or literature review has ever examined the cleaning and disinfecting properties of a soap that may be made from oil that is derived from insects. If this idea gains momentum, it can deal with the twin challenges of greenhouse gas release from food waste in landfills and the habitat destruction that results from increased demand for oil palm plantations because my project is pointing towards sustainable alternatives that do not require the same area of land. In fact, no new land would be required to house black soldier fly larvae because they can be kept in enormous numbers in vacant lots and abandoned buildings. They are very adaptable; all they need is ultraviolet light for breeding purposes and a consistent source of warmth.

a. Is there some aspect of your project's objective, or how you achieved it that you haven't done before?

While I had made soap from the black soldier fly larvae before, I had not tested how effective it was in comparison to other soaps in terms of its cleaning properties and disinfecting abilities. This made me think of new protocols and new ways to gather data, and led me to the protocols that are described in my research paper.

b. Is your project's objective, or the way you implemented it, different from anything you have seen?

The two methods that I developed to examine how well these soaps can clean and disinfect were my own creation; I had not found anything like these within the scientific literature but I thought that they both might work well. The additional challenge was how to conduct these safely within a high school setting, but I think that my protocols were effective, logical, and safe. This is why I used nontoxic black eye grease and a strain of E. coli bacteria that is deemed safe for use in kindergarten through 12th grade classrooms. In addition, my project's objective was the first to use insect oil in a non-food commercial product; previous experiments mostly focused on animal feed or ingredients for human food.

c. If you believe your work to be unique in some way, what research have you done to confirm that it is?

I have read other papers that discussed the cleaning abilities of soap, but the ones that I saw generally worked with human skin which seemed too variable and there was a potential for harm from overwashing. This is why I came up with the idea of using "practice" skin made from silicone for tatooing. The use of a bacterial culture with a known concentration of safe E. coli and nontoxic black grease used by athletes was also unique, because these were not in the articles that I reviewed. I have also not found any experiments that had been previously performed to see how oil derived from black soldier fly larvae might work as an ingredient in soap.

4. What was the most challenging part of completing your project?

Time was the hardest aspect, because I needed to find a new place to live within this timeframe and I have narcolepsy so it is not always easy for me to get to school on time. I also wanted to find some way to eliminate the disagreeable color and odor from the BSFL oil, but did not have the time and resources to do it. My plan had been to test a steam distillation apparatus to see if that might work to deodorize and decolor BSFL oil, but have only recently secured the equipment and I cannot include it in this round of research.

a. What problems did you encounter, and how did you overcome them?

I stayed many days after school, and did a lot of work during lunch and free periods. I also needed to get the materials relatively quickly, and so I needed to purchase them through Amazon.com with the money that I could make by selling sustainable soaps that did not contain black soldier fly oil. It appears to me that funding is always a big problem in science, especially for research, and I was fortunate to be able to make high-quality soap on the side to secure the resources that I needed. I also needed to leave my after school job in order to find enough time to complete this experiment.

b. What did you learn from overcoming these problems?

I have learned that there are many paths to a goal, and if one doesn't work, I just need to sit and think about alternatives. There are also people who are willing to help; I just need to trust them. Support from other people is the only way to make big projects happen, even if that just means somebody bringing me food because I missed breakfast from oversleeping.

5. If you were going to do this project again, are there any things you would you do differently the next time?

I would make sure that I had more time to complete all of the dimensions, so that I was not rushing. I would also like to consider new substances that I could try for cleaning. In this round, before the black grease that I used, I had considered peanut butter for both its fatty component and its distinctive smell, but decided that would be too dangerous in a school setting. In the new house where I needed to move with a community member, the owner has offered me a basement where I might be able to try other substances that would be allergens at the high school. I would also make sure that I secured the steam distillation apparatus sooner, now that I know where to find one.

6. Did working on this project give you any ideas for other projects?

Yes, I want to test BSFL oil in other cosmetic products that normally use palm oil, as well as investigate ways that the black soldier fly larva oil can be processed and refined for a better color and smell. At present, this oil does not look very pleasant, and it has a nutty odor. This is why I want to try steam distillation and see what the product might be. There is also the possibility of hydrogenating BSFL oil in order to make a sustainable wax like the soy wax that is used to make candles, or possibly incorporating it into a biodegradable plastic. The quantity of plastic that is currently in our oceans is very disturbing for me, and while I know that some biodegradable plastics can be made from algae, I would like to determine of we might use the hydrocarbons found in BSFL oil to make plastics that are ultimately derived from food waste and will safely degrade if they are dumped into waterways.

7. How did COVID-19 affect the completion of your project?

The pandemic did not affect me a great deal, because I stayed healthy and there were no restrictions when I was at school. The only challenge is that I did not learn as much English as I should have during 2020 and 2021, because classes were not as easy for engagement and I was living with my Spanish-speaking family. Now that I am living with an English-speaking woman, I am speaking English more, but I have been relying on Google translate in many different situations. I am hoping that I can now become more independent.